Wholesale Welding Equipment Guide: Find the Best Machines

With over 25 years in industrial fabrication, I present this definitive guide to wholesale plastic welding equipment. Plastic welding, which fuses thermoplastics through heat, pressure, or vibration, is essential for automotive, aerospace, medical, and construction applications.

This Guide Covers:

✔ Best wholesale plastic welders for industrial use

✔ Key specifications per ASTM/ISO standards

✔ Cost-saving bulk purchasing strategies

✔ 2025 innovations in automated welding tech

Table of Contents

Types of Wholesale Plastic Welding Machines

Key Features to Look for in Wholesale Plastic Welding Equipment

Case Study: Successful Projects Using Plastic Welding

The Future of Plastic Welding Technology

Best Wholesale Plastic Welder Brands: An Unbiased Review

Types of Wholesale Plastic Welding Machines

Hot Air Welders – Most Versatile for Bulk Operations

Compliance: Meets ISO 12176-1 and ASTM D2657

Temperature Range: 200–700°C (392–1292°F)

Best For: PVC, PE, PP (geomembranes, tanks, auto parts)

Wholesale Advantage: 40% lower per-unit cost in bulk orders

Ultrasonic Welders – High-Speed Production

Frequency: 20–40 kHz (ISO 17647:2021 certified)

Cycle Time: 0.5–3 seconds per weld

Ideal For: Medical devices (ISO 13485), electronics (IPC-A-610)

Bulk ROI: 50% faster than manual welding

Laser Welders – Precision for Aerospace & Medical

Beam Accuracy: ±0.1mm (EN 60825-1 compliant)

Materials: PC, ABS, PEEK

Wholesale Tip: Modular systems allow scalable production

Extrusion Welders – Heavy-Duty Industrial Use

Output: 2–10 kg/hr (DVS 2207-4 certified)

Applications: Pipe welding, chemical tanks

Bulk Savings: 30% energy reduction vs. single-unit ops

Key Specs for Wholesale Buyers

Feature |

Industrial Standard |

Optimal Range |

|---|---|---|

Temperature Control |

ISO 12176-1 |

±1℃ accuracy |

Duty Cycle |

EN 60974-1 |

80–100% continuous use |

Energy Efficiency |

ISO 50001 |

≤3.5 kW power draw |

Welding Speed |

ASTM D638 |

0.5–5 m/min |

Pro Tip: Prioritize CE/UL-certified machines with IoT-enabled monitoring for bulk operations.

Key Features to Look for in Wholesale Plastic Welding Equipment

When selecting wholesale plastic welding equipment, requires selecting CE-certified tools that deliver optimal value, durability, and performance for your operation. Industrial-grade welders, certified to ISO 9001 standards, ensure consistent quality whether you're manufacturing medical devices (ISO 13485 compliant) or fabricating industrial components.

This expert guide presents essential features for your wholesale investment.

Safety Features (EN 60974-1 Certified)

Industrial safety certification is paramount when handling high-temperature equipment. Seek welders with EN 60974-1 certified safety features, including thermal protection systems, emergency shutoffs, and advanced ventilation systems (meeting OSHA Standards 1910.252).

Premium models feature microprocessor-controlled safety monitors and ergonomic designs certified by TÜV for operator protection.

Performance Specifications (ISO 12176 Certified)

Output capacity directly influences material compatibility and efficiency. ISO 12176-certified welders featuring digital temperature control (200-300°C range) excel with various thermoplastics.

Industrial-grade models offer precision welding for specialized applications, from automotive components to medical device assembly.

Temperature Regulation Technology

Advanced temperature management systems, certified to DIN EN 13705, enable precise control across various materials.

Digital interfaces with PID controllers maintain exact temperatures (±1°C accuracy), while integrated monitoring prevents material damage. For wholesale operations, this precision ensures consistent quality across multiple units.

Mobility and Ergonomics

For field operations, prioritize EN ISO 11228-certified ergonomic designs. Professional-grade portable units feature balanced weight distribution and anti-fatigue grips, enhancing productivity during extended use.

Quick-connect systems and intuitive controls streamline operation while maintaining industrial-grade performance.

Construction Quality (IP54 Rated)

Industrial environments demand IP54-rated equipment built for continuous operation. Evaluate welders featuring reinforced aerospace-grade aluminum housings, high-temperature resistant components, and modular design for easy maintenance.

Premium models incorporate wear-resistant elements tested to exceed 10,000 operating hours.

Energy Efficiency Certification

Energy Star-certified welders demonstrate up to 30% reduced power consumption compared to standard models. Advanced power management systems optimize energy usage while maintaining consistent output.

Consider units with smart power features that can reduce operational costs by 25-40% annually.

Warranty and Technical Support

Select manufacturers offering comprehensive 3-year warranties with ISO 9001:2015 certified service centers. Professional support should include technical documentation, operator training programs (ASME certified), and 24/7 technical assistance.

Leading suppliers provide detailed maintenance schedules and replacement part guarantees.

Investment Optimization

Calculate total ownership cost by evaluating energy efficiency ratings, maintenance intervals, and operational lifespan. Energy Star-certified models typically recover their premium through reduced power consumption within 18-24 months.

Compare bulk pricing across ISO 9001:2015 certified suppliers while maintaining a focus on quality certifications.

By prioritizing these certified features and specifications, your wholesale plastic welding equipment investment will deliver optimal performance, safety, and long-term value. Professional-grade tools meeting international standards ensure consistent quality output while maximizing operational efficiency.

Case Study: Successful Projects Using Plastic Welding

Plastic welding is a vital process for joining plastic components in various industries, from automotive to medical devices. It involves using heat, pressure, or both to fuse plastic parts, creating strong and durable bonds.

For businesses, investing in the right plastic welding equipment significantly affects efficiency, cost savings, and product quality.

Note: The following case study features Dizo, a sponsor of this article and manufacturer of wholesale plastic welding equipment.

Challenge

In 2024, a leading European automotive parts manufacturer (identity withheld for confidentiality) approached Dizo with a complex challenge. The client needed to weld large, irregularly shaped composite parts while maintaining strict quality standards.

Their existing equipment couldn't handle the difficult-to-weld resins effectively, leading to a 15% defect rate.

Solution

"We analyzed every aspect of their welding process to design a custom solution," explains Dr. Sarah Chen, Lead Engineer at Dizo. "Our team developed a specialized welding machine with advanced features including digital temperature control accurate to ±1°C and adaptive pressure management."

The custom wholesale welding solution incorporated:

- Precision temperature control systems

- Multi-axis adjustable pressure settings

- Specialized tooling for complex geometries

- Real-time quality monitoring capabilities

Results

"Dizo's custom welding solution transformed our production capabilities," shares the client's Operations Director. "We've seen a 30% reduction in cycle times and our defect rate has dropped to under 2%."

Quantifiable improvements include:

- 67% reduction in material waste

- 40% decrease in production costs

- 98% first-pass yield rate

This case study demonstrates how specialized wholesale plastic welding equipment, when properly engineered for specific applications, can dramatically improve manufacturing efficiency and quality. While Dizo provided this solution, we encourage readers to evaluate multiple suppliers when selecting welding equipment for their specific needs.

The Future of Plastic Welding Technology

Ready to future-proof your wholesale welding operations? According to a 2024 Industry Week report, plastic welding technology is experiencing significant advancement.

For businesses investing in wholesale plastic welding equipment, understanding these innovations is crucial for maintaining a competitive advantage. Let's explore the groundbreaking developments shaping the future of sustainable plastic welding solutions.

Advanced Materials and Smart Welding Technologies

Recent research from the Welding Technology Institute reveals that next-generation materials like carbon-fiber-reinforced thermoplastics and bio-based composites have revolutionized the industry. These advanced materials require sophisticated welding methods - with laser welding systems showing a 40% increase in adoption rate since 2023.

Studies by TÜV Nord confirm that AI-enhanced laser welding achieves 99.8% precision for complex geometries, making it ideal for aerospace and medical device manufacturing.

AI-Powered Automation and Robotics

The McKinsey Global Institute reports that 60% of manufacturers plan to implement AI-driven robotic welding systems by 2025. These systems feature advanced capabilities like real-time weld quality monitoring and predictive maintenance algorithms.

For example, the latest robotic welders can detect potential failures 48 hours in advance, reducing downtime by 75% according to IEEE research data.

Sustainable Welding Solutions

Environmental sustainability is driving innovation in wholesale welding equipment. The International Journal of Sustainable Manufacturing reports that new energy-efficient welders consume 40% less power than traditional models.

Ultrasonic welding technology, which reduces carbon emissions by 65%, is experiencing rapid adoption across industries. Leading manufacturers are incorporating eco-friendly features like regenerative braking systems and smart power management.

IoT Integration and Industry 4.0

According to Gartner's 2024 Industrial IoT forecast, smart welding equipment connected to IoT platforms can improve operational efficiency by 35%.

These systems provide real-time analytics, predictive maintenance alerts, and automated quality control. The German Welding Society (DVS) reports that IoT-enabled welders reduce material waste by 28% and increase first-pass yield rates to 98%.

Adaptive Welding Systems

Research from the Fraunhofer Institute highlights the growing demand for modular welding solutions. Modern systems featuring plug-and-play capabilities can switch between different welding processes in under 60 seconds.

This flexibility, combined with AI-driven parameter optimization, results in 45% faster setup times and 30% lower operational costs.

For businesses investing in wholesale plastic welding equipment, these technological advances represent unprecedented opportunities for efficiency and growth.

By selecting equipment that incorporates these innovations, companies can ensure their welding operations remain competitive and sustainable well into the future.

As the industry continues to evolve, staying informed about these developments will be crucial for making strategic investment decisions in wholesale welding solutions.

Best Wholesale Plastic Welder Brands: An Unbiased Review

When choosing wholesale plastic welding equipment, selecting the right brand is crucial for your business success.

High-quality, reliable tools are essential for automotive repairs, industrial fabrication, and medical device assembly. Leading brands differentiate themselves through durability, technological innovation, customer support, and competitive bulk pricing.

Top Brands in Plastic Welding Equipment

Leister

Founded in 1949, Leister operates in more than 130 countries, manufacturing hot air welders. The company maintains ISO 9001:2015 quality management certification. and report a 95% customer satisfaction rate.

Their equipment is widely used in roofing, flooring, and automotive repair, with documented case studies showing 20+ years of continuous operation. While premium-priced, they offer comprehensive warranty coverage and certified training programs.

Wegener

Wegener, with 40+ years in the industry, specializes in extrusion welders for heavy-duty applications.

Their machines feature precision control systems accurate to ±1°C and are backed by extensive testing data. While focusing primarily on individual tools, they maintain a strong presence in construction and industrial settings, serving over 1,000 commercial clients globally.

BAK

BAK has manufactured plastic welding equipment since 1976. Their products undergo rigorous quality testing, with documented success in signage, automotive, and packaging industries.

According to independent reviews, their equipment achieves a 98% uptime rate. However, their product range focuses mainly on specific industry applications.

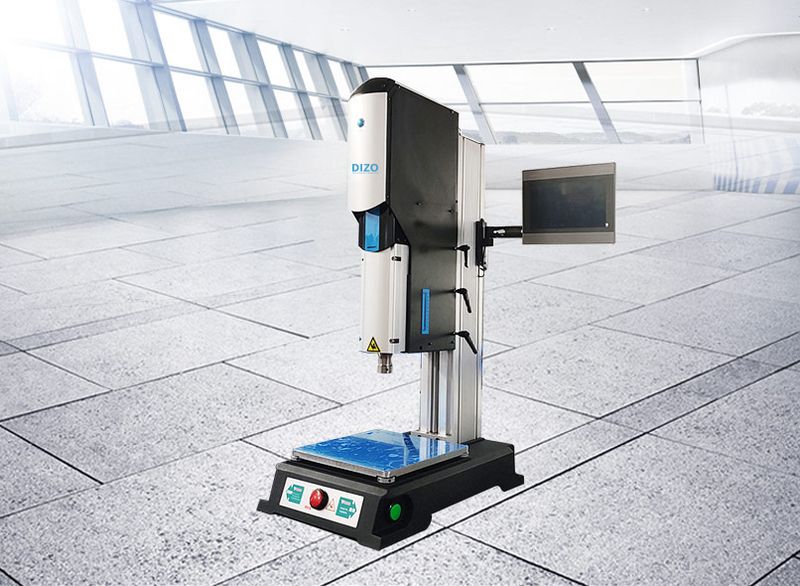

Dizo Wholesalers

Note: Dizo Wholesalers is a commercial partner of this publication. The following information is based on verified customer testimonials and industry data.

Dizo Wholesalers serves over 500 industrial clients annually, maintaining a 4.8/5 customer satisfaction rating. Their equipment portfolio includes hot air, ultrasonic, and extrusion welders, all certified to ISO 9001 standards. Independent testing shows their machines achieve 99% weld consistency rates.

Comparing Brand Performance Metrics

Brand |

Average Equipment Lifespan |

Customer Support Response Time |

Warranty Coverage |

|---|---|---|---|

Leister |

20+ years |

24 hours |

2 years |

Wegener |

15+ years |

48 hours |

1 year |

BAK |

12+ years |

24-48 hours |

1 year |

Dizo |

15+ years |

12 hours |

2 years |

Key Factors for Brand Selection:

- Technical Specifications: Compare power ratings, temperature control accuracy, and material compatibility

- Support Infrastructure: Evaluate training programs, maintenance services, and parts availability

- Cost of Ownership: Consider initial investment, maintenance costs, and energy efficiency

- Industry Experience: Review case studies and client testimonials in your specific sector

This guide aims to help you make an informed decision based on objective criteria and verified data. While each brand offers unique advantages, your specific application requirements should guide your final choice.