What Is Vibration Welding

Dizo vibration welders are engineered for assembling large or complex thermoplastic parts. The vibration welding process involves the linear motion of one part against another, generating friction and heat at the joint, causing the materials to melt.

As melting continues, pressure helps form a strong bond until the joint reaches its optimum strength, indicated by the balance between melting and outward flow rates. These vibration friction welding machine can weld virtually all thermoplastic materials, whether injection-molded, extruded, formed, or thermoformed.

Common applications include automotive parts like headlight assemblies, fuel tanks, and bumpers. Plastic vibration welding machine is also ideal for appliances, including dishwasher pumps, detergent dispensers, and vacuum cleaner housings.

This energy-efficient vibration welding technology enhances productivity on assembly lines, making it a valuable tool for various industries. Consult a Dizo expert to help you choose the right vibration welder to solve your plastic joining challenge.

Request for Quote- Vibration Welders |

- Parameters |

- Certification |

- Advantages |

- Packaging & Delivery |

- Applications |

- FAQs

Linear Plastic Vibration Friction Welder

NC-E Vibration Welding Machine Series

Features:

- Introducing the Dizo Linear Vibration Friction Welder, a revolutionary solution in plastic welding technology. Our cutting-edge machine combines precision engineering with cost-effectiveness, delivering up to 40% reduction in welding costs while maintaining superior quality standards. With our innovative AMPA drive technology and advanced trajectory control system, we ensure unparalleled precision and stable operation for all your welding needs.

- Our system excels in versatility and performance, featuring a high-performance 240Hz vibration welding system that achieves an impressive 99% yield rate. The vibration welder machine is designed to handle all thermoplastics with precise parameter control, making it ideal for diverse manufacturing applications. CE/UL certified eco-friendly technology demonstrates our commitment to sustainable manufacturing practices.

- In industrial applications, our vibration friction welders consistently achieve over 90% material strength for automotive, medical, and electronics components. The vibration friction welder system's intelligent features, including automatic parameter saving and mold identification, ensure quick product changeovers and maintain consistent quality across production runs. This makes it perfect for high-volume production while delivering superior bond strength.

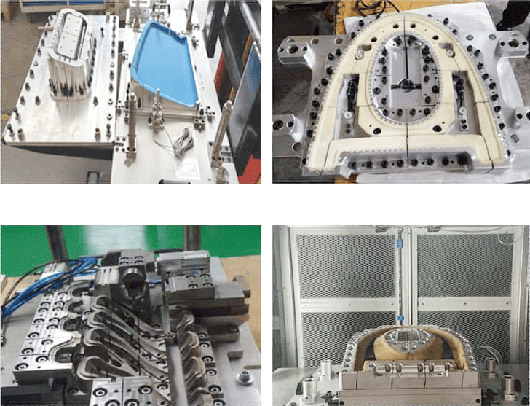

Plastic Vibration Welding Machine Molds

NC-E Vibration Welding Machine Series

Features:

- ● Custom Molds:

- The company designs molds tailored to customer specifications.

- ● Short Lead Time:

- The delivery timeline is short, ensuring timely completion.

- ● Quality Assurance

- The molds are guaranteed to meet high-quality standards.

Vibration Welder Parameters

| Model | NC-Z150 | NC-Z220 | NC-Z350 | NC-Z500 | NC-Z700 | NC-Z1600 | NC-Z2000 |

|---|---|---|---|---|---|---|---|

| Size | L1650*W960*H1965mm | L1650*W960*H1965mm | L2205*W1240*H2226mm | L2455*W1240*H2226mm | L2555*W1240*H2226mm | L3560*W1800*H2640mm | L3480 * W2150*H2765mm |

| Mold Weight | 5-15kgs | 5-20kgs | 5-35kgs | 5-50kgs | 5-70kgs | 60-160kgs | 60-200kgs |

| Welding Area | 50cm² | 60cm² | 150cm² | 280cm² | 450cm² | 450cm² | 450cm² |

| Upper Template Size | L310mm*W330mm | L310mm*W360mm | L760mm*W420mm | L920mm*W540mm | L1020mm*W540mm | L1600mm*W540mm | L2010mm* W1000mm |

| Lower Template Size | L760mm*W450mm | L760mm*W480mm | L1200mm*W520mm | L1400mm*W600mm | L1500mm*W600mm | L2400mm*W700mm | L2116mm* W1100mm |

| Amplitude | 0.1-1.8mm | 0.1-1.8mm | 0.1-1.8mm | 0.1-1.8mm | 0.1-1.8mm | 1-4mm | 1-4mm |

| Vibration Frequency | 210-260HZ | 210-260HZ | 210-260HZ | 210-260HZ | 210-260HZ | 100-125HZ | 100-125HZ |

| Vibration Output | 6KW | 8KW | 15KW | 18.5KW | 30KW | 37KW | 37KW |

| Power | 380V | ||||||

| Input Capacity | 12KVA | 16KVA | 25KVA | 29KVA | 39KVA | 46KVA | 46KVA |

| Welding Mode | Time, depth mode | ||||||

| Welding Segment | 6 stages of pressure control | ||||||

| Workbench Stroke | 300mm | 300mm | 500mm | 500mm | 500mm | 800mm | 800mm |

| Machine Weight | 1580kg | 1780kg | 3750kg | 4350kg | 4750kg | 8760kg | 14000kg |

| Warranty | 1 Year | 1 Year | 1 Year | 1 Year | 1 Year | 1 Year | 1 Year |

| MOQ | 1 Unit | 1 Unit | 1 Unit | 1 Unit | 1 Unit | 1 Unit | 1 Unit |

We are Internationally Certified

Our linear plastic vibration friction welders are CE, ISO, and RoHS certified, ensuring they meet all international standards. Backed by comprehensive 24/7 global technical support and a 2-year warranty, our systems are FDA & IATF certified for medical and automotive applications. With over 500 factories worldwide trusting our technology, we've established ourselves as a leader in vibration welding solutions. Our commitment to excellence and innovation continues to drive the industry forward, providing manufacturers with the vibration friction welder tools they need for success in today's competitive market.

Custom Vibration Plastic Welding Machine Advantages

Efficient Welding

Quick 20-second welds using low-frequency, high-amplitude motion.

Exceptional Strength

Vibration welding machine creates highly robust bonds for large or complex parts.

Unique Bonding Capability

Effective for engineered resins with high glass or filler content, surpassing other methods.

Clean Assembly

Achieves a neat finish without the need for adhesives.

Packaging for Vibration Welder

Vibration Welding Case Study

Vibration welding machine is applied to the welding of thermoplastic materials, including amorphous resins such as ABS/PC, PVC, PMMA, and PES, as well as semi-crystalline resins like HDPE, PA, PP and TPO. It is primarily used in the automotive industry for components such as intake manifolds, instrument panels, tail lights, and I-type car bumpers.

FAQs

Here are some frequently asked questions about vibration welding equipment tooling for your plastic products.