Industry Application

- Automotive |

- Household Appliances |

- Consumer Electronics |

- New Energy |

- Medical Device |

- Toys |

- Packaging |

- Non-woven Fabric

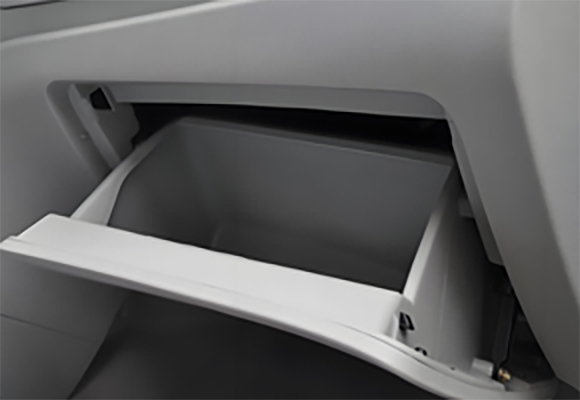

Automotive Industry

Precision Welding for Interior Components

A global automotive supplier faced a critical challenge: assembling a complex plastic interior console piece for a new vehicle model within a tight production deadline. Traditional welding methods were too slow and inconsistent, risking delays in the product launch.

Solution:

We developed a custom ultrasonic welding machine equipped with dual 35kHz ultrasonic welding stacks and precision pneumatic actuators. The system was designed to simultaneously weld two points on the console piece in under 10 seconds per cycle. Advanced features, such as end-of-weld energy feedback and a rigid mechanical stop, ensured consistent weld quality and surface finish.

Result:

The machine was delivered in just 12 weeks, significantly faster than the industry standard lead time. The customer successfully met their production deadline, and the Corporate Tooling and Process Manager commended our technical expertise and on-time delivery.

Household Appliances Industry

Efficient Assembly for Durable Goods

A leading household appliance manufacturer needed a solution to assemble plastic components for washing machines and refrigerators. The challenge was to create strong, durable bonds that could withstand daily wear and tear while maintaining a sleek, seamless appearance.

Solution:

We deployed a vibration welding system capable of joining large, irregularly shaped parts with high precision. The system used frictional heat to create strong, hermetic bonds, ensuring the durability and reliability of the final products.

Result:

The manufacturer achieved a 15% improvement in production efficiency and a significant reduction in material waste. The welded components met all performance and aesthetic standards, enhancing the overall quality and longevity of their appliances.

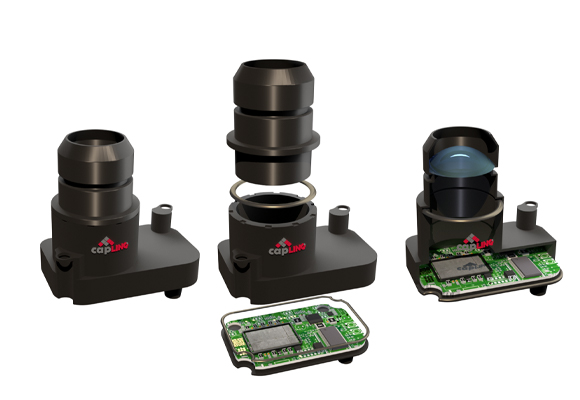

Consumer Electronics Industry

Waterproof Seals for Consumer Devices

A consumer electronics company sought to improve the durability and water resistance of their smartphone cases and earbuds. Traditional assembly methods often resulted in weak seals and inconsistent quality.

Solution:

We implemented an ultrasonic welding system that used focused laser beams to create precise, non-contact welds. This method minimized thermal distortion and produced clean, aesthetically pleasing joints. The system was integrated into the company’s automated production line, enabling high-speed, high-volume manufacturing.

Result:

The company reported a 20% increase in production efficiency and a significant reduction in product returns due to water damage. The improved weld quality also enhanced the overall durability and user experience of their devices.

New Energy Industry

Sealing Solutions for Battery Components

A manufacturer in the new energy sector needed a reliable method to assemble battery housings and components for electric vehicles (EVs). The challenge was to create strong, leak-proof seals that could withstand extreme temperatures and vibrations while maintaining electrical insulation.

Solution:

We implemented an ultrasonic welding system tailored for joining thermoplastic battery housings. The system provided precise and durable welds that ensured airtight seals and maintained the integrity of the battery components. The process was optimized for high-speed production to meet the growing demand for EV batteries.

Result:

The manufacturer achieved a 25% improvement in production efficiency and a significant reduction in defect rates. The welded battery housings met all safety and performance standards, contributing to the reliability and longevity of electric vehicles.

Medical Device Industry

Hermetic Sealing for Critical Equipment

A leading medical device manufacturer needed to assemble IV components and surgical instruments with leak-proof, biocompatible bonds. Precision and sterility were paramount, and traditional methods fell short of meeting their stringent requirements.

Solution:

We provided an ultrasonic welding system capable of creating strong, hermetic seals without the use of adhesives or solvents. The system was designed to handle intricate geometries and ensure consistent weld quality, even for high-volume production.

Result:

The manufacturer achieved a significant reduction in production time and costs while maintaining the highest standards of quality and safety. The welded components met all regulatory requirements, ensuring reliability in critical healthcare applications.

Toy Industry

Durable and Safe Assembly for Children’s Products

A toy manufacturer faced challenges in assembling plastic components for children’s toys. The process required durable, aesthetically pleasing bonds that could withstand rough handling while meeting strict safety regulations.

Solution:

We provided an ultrasonic welding system that used controlled heat and pressure to create strong, seamless joints. The system was designed to handle a variety of plastic materials and complex shapes, ensuring consistent quality and safety across all products.

Result:

The manufacturer achieved a 20% reduction in assembly time and a significant improvement in product durability. The welded toys passed all safety tests, giving parents peace of mind and enhancing the brand’s reputation for quality.

Packaging Industry

Sustainable Sealing for Food and Beverage Containers

A packaging manufacturer aimed to reduce waste and improve the sustainability of their food and beverage containers. They needed a solution that could create airtight seals using thinner, more eco-friendly materials.

Solution:

We deployed an ultrasonic welding system that used controlled heat and pressure to join thermoplastic materials. The system was optimized for thin films and could handle a variety of materials, including recycled plastics.

Result:

The manufacturer achieved a 30% reduction in material usage while maintaining the strength and integrity of their packaging. The system also supported their sustainability goals by enabling the use of biodegradable and recycled materials.

Non-Woven Fabric Industry

Bonding for Filtration and Medical Products

A producer of non-woven fabrics for filtration systems and medical products required a solution to bond layers of fabric without compromising their porosity or structural integrity. Traditional adhesive methods were unsuitable due to the risk of contamination and inconsistent bonding.

Solution:

We introduced an ultrasonic welding system specifically designed for non-woven fabrics. The system used high-frequency vibrations to create strong, uniform bonds without the need for adhesives. It was capable of handling delicate materials and complex patterns, ensuring consistent quality across high-volume production runs.

Result:

The customer reported a 30% increase in production speed and a significant reduction in material waste. The welded non-woven fabrics met stringent quality standards, making them ideal for use in medical masks, air filters, and other critical applications.

Quote Now

Quote Now