Unveiling the Intricacies of the Plastic Hot Plate Welder Process

Plastic hot plate welding is a highly effective and widely used technique for joining thermoplastic materials. This process has gained immense popularity across industries such as automotive, aerospace, electronics, manufacturing, and medical, due to its ability to create strong and durable bonds. In this comprehensive article, we will provide an in-depth exploration of the step-by-step process of plastic hot plate welding, emphasizing its advantages, considerations, recent advancements, and various applications.

Step-by-Step Guide to the Plastic Hot Plate Welder Process

- Material Preparation: Before commencing the welding process, it is imperative to ensure that the materials to be welded are meticulously prepared. This involves cleaning the surfaces of the plastic parts to remove any contaminants that could hinder the welding process. Additionally, attention should be given to the surface finish, as a smooth surface promotes optimal adhesion between the plastic pieces.

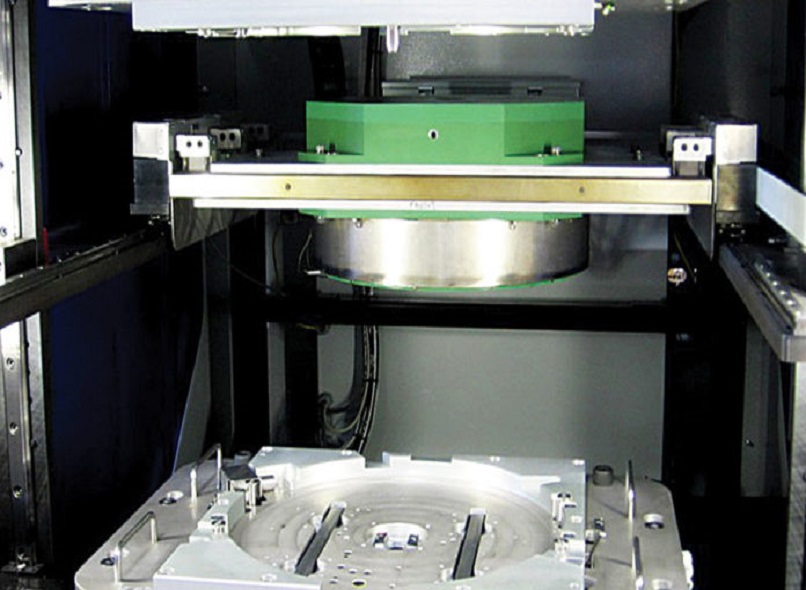

- Equipment Setup: Position the hot plate welding machine on a stable surface, ensuring that it is in proper working condition. Referring to the manufacturer's guidelines, determine the appropriate temperature for welding the specific type of plastic. Adjust the temperature of the hot plate accordingly to meet the specific requirements of the plastic material.

- Clamping: Carefully place the plastic pieces onto the hot plate, ensuring proper alignment. To maintain alignment during the welding process, secure the pieces in place using clamps or fixtures. This step is crucial for achieving a tight and uniform joint.

- Heating the Surfaces: Activate the hot plate and allow it to reach the designated temperature. The heat generated by the hot plate will soften and melt the surfaces of the plastic pieces, preparing them for bonding. Monitoring the temperature closely is essential to prevent overheating or damaging the plastic material.

- Joining the Materials: Once the surfaces are adequately heated, remove the plastic pieces from the hot plate and quickly bring them together. Apply sufficient pressure to ensure proper contact between the melted surfaces. The pressure helps facilitate material flow and promotes a strong bond. The specific pressure and duration of pressure application depend on the plastic material and the desired strength of the weld joint.

- Cooling and Solidification: Hold the joined pieces together for a predetermined amount of time to allow the melted plastic to cool and solidify. This cooling process is crucial for ensuring the long-term strength and stability of the weld joint. The cooling time required may vary based on factors such as the size and thickness of the welded components.

- Finishing Touches: Once the weld joint has cooled and solidified, inspect it for any defects or imperfections. Carefully remove any excess material or flash using appropriate tools to achieve the desired final shape and appearance. Conduct a thorough examination to ensure the weld is of high quality and meets the required specifications.

Advantages and Considerations for Plastic Hot Plate Welding

Plastic hot plate welding offers several advantages when used for joining plastic materials:

- High Strength: Plastic hot plate welding creates weld joints that exhibit high strength and durability, comparable to the original plastic material. This ensures the longevity and reliability of the assembled products.

- Leak-Tight Seals: The hot plate welding process produces weld joints with excellent sealing properties. This makes it ideal for applications that require leak-tight connections, such as in the automotive, medical, and plumbing industries.

- Versatility: Plastic hot plate welding can be performed on plastic components of various sizes and complexities. It is particularly effective for joining large or irregularly shaped parts that may be challenging to weld using other techniques.

- Compatibility: Plastic hot plate welding is highly compatible with a wide range of thermoplastic materials. The process effectively fuses plastic pieces together, creating strong and uniform welds.

While plastic hot plate welding is a versatile and efficient method for joining plastic components, there are a few considerations to keep in mind:

- Temperature Sensitivity: Different types of plastics have different temperature sensitivities. It is crucial to carefully control the temperature to prevent any adverse effects during the welding process, such as degradation or undesirable changes in the plastic properties.

- Material Compatibility: Although plastic hot plate welding is well-suited for welding a wide range of thermoplastic materials, it is important to assess the compatibility of different materials before attempting the hot plate welding process.

- Process Control: Achieving optimal weld quality requires precise control of the heating and cooling cycles. Overheating or insufficient fusion can result in weak welds. Manufacturers must carefully consider the material properties and design requirements to ensure proper process control.

Applications of Plastic Hot Plate Welding

Plastic hot plate welding finds extensive applications in various industries, including:

- Automotive: Plastic hot plate welding is widely used in the automotive industry for joining plastic components such as bumpers, fuel tanks, interior trim panels, and ventilation systems. The process ensures strong and durable bonds, contributing to the overall safety and performance of vehicles.

- Aerospace: Plastic hot plate welding plays a crucial role in the aerospace industry for joining plastic parts in aircraft interiors, including panels, seat components, and air ducts. The process enables lightweight construction while maintaining structural integrity.

- Electronics: Plastic hot plate welding is employed in the electronics industry for joining plastic components in devices such as smartphones, laptops, and consumer electronics. The process ensures reliable connections and enhances the overall durability of electronic products.

- Manufacturing: Plastic hot plate welding finds extensive use in general manufacturing processes for joining plastic parts in various products such as appliances, medical devices, packaging materials, and household items. The process offers versatility and cost-effectiveness.

Recent Advancements in Plastic Hot Plate Welding Technology

In recent years, there have been significant advancements in plastic hot plate welding technology, further enhancing its efficiency, reliability, and versatility. These advancements include:

- Temperature Regulation: The integration of temperature sensors and feedback control systems allows for more precise temperature regulation during the welding process. This ensures consistent and optimal welding conditions, improving the quality and reliability of the weld joints.

- Advanced Heating Elements: The use of advanced materials, such as ceramic composites, for the heating element has enhanced heat transfer efficiency and durability. These materials enable more efficient heating and contribute to the overall performance of the plastic hot plate welding process.

- Automation and Robotics: The integration of automation and robotics into plastic hot plate welding systems has revolutionized the industry. Automated systems enable high-speed and consistent weld production, increasing productivity and reducing human error. This integration ensures repeatability and consistency in the welding process, resulting in superior quality weld joints.

- Sustainability Considerations: Plastic hot plate welding also contributes to sustainability efforts in the field of plastic fabrication. By creating strong and durable bonds between plastic parts, it reduces the need for additional fasteners or adhesives that can contribute to waste and environmental impact. The process also minimizes the risk of material failure or separation over time, extending the lifespan of the assembled products.

Conclusion

Plastic hot plate welding is an effective and reliable method for joining plastic components. By following the step-by-step process and considering the advantages, considerations, and recent advancements, manufacturers can achieve strong and durable weld joints. Plastic hot plate welding offers versatility, high strength, and leak-tight seals, making it a valuable technique in a wide range of industries. As technology continues to advance, the field of plastic hot plate welding is poised to deliver even more efficient and sustainable joining solutions for plastic and other thermoplastic materials.