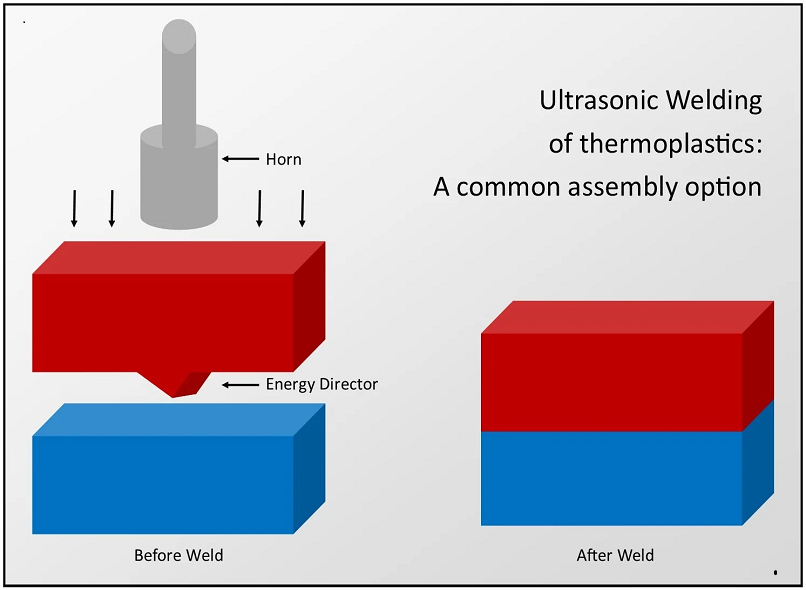

What is an Energy Director in Ultrasonic Welding?

Ultrasonic welding is an incredibly important manufacturing process that is widely used for joining two thermoplastic materials. It is a process that involves the application of high-frequency ultrasonic vibrations and pressure to create a strong bond between the materials. One of the most important and fascinating elements of ultrasonic welding is the use of an energy director.

An energy director is a raised feature on one of the two plastic parts that are being joined together. It is designed in a way that focuses the ultrasonic energy and creates a significant amount of frictional heat between the two parts. This heat causes the plastic material to melt and fuse together, creating a strong and durable bond. The energy director is an essential component that plays a critical role in the success and efficiency of the ultrasonic welding process.

It is important to note that the shape and size of the energy director are crucial factors that determine the success of the ultrasonic welding process. The energy director should be positioned in a way that allows for maximum energy transfer and should be designed to produce the right amount of heat for the specific materials being joined. Additionally, the customization of energy directors can be done according to the specific requirements of the manufacturing process, making it a versatile tool for joining different thermoplastic materials.

Furthermore, engineers and manufacturers can experiment with different energy director designs to determine the best configuration for their specific needs. Proper training and education on energy director usage can also ensure that the ultrasonic welding process is optimized for maximum efficiency and effectiveness.

In summary, energy directors are a vital and intriguing component of ultrasonic welding. They allow for the creation of strong and durable bonds between two thermoplastic materials by focusing ultrasonic energy and creating frictional heat. The customization and proper implementation of energy directors can greatly enhance the success and efficiency of ultrasonic welding processes, making it an exciting and important area of study for engineers and manufacturers alike. The use of energy directors has revolutionized the way we join thermoplastic materials, and it is an area of ongoing development and research in the field of manufacturing.