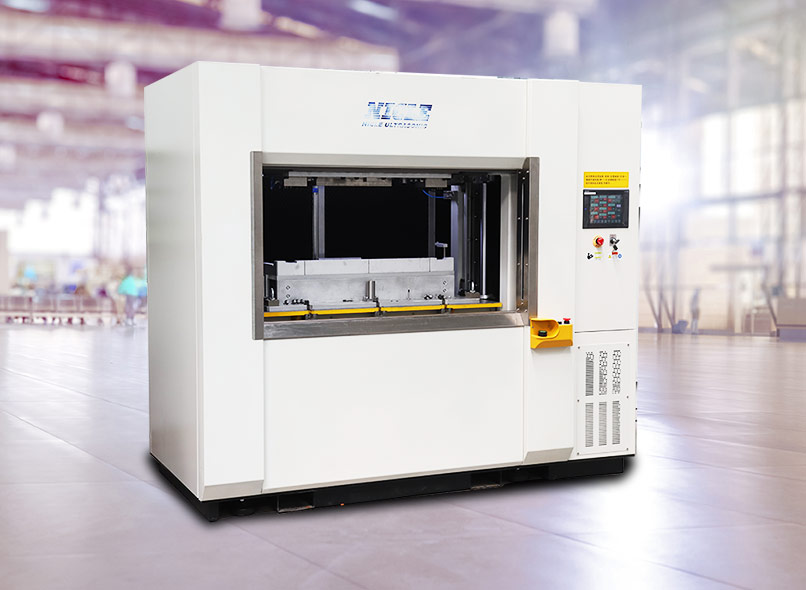

NC-Z Series Vibration Welders

Automotive Industry

Vibration welding machines have been widely used in the automotive industry due to their ability to join thermoplastic parts with high strength and tightness. This technology is particularly useful in the production of automotive parts, such as bumpers, instrument panels, and air ducts.

Medical Equipment

Vibration welding machines are becoming increasingly popular in the medical industry due to their versatility and effectiveness in joining plastic components. In particular, they have been used to create medical devices such as catheters, IV sets, and blood filters.

Household Appliances

Vibration welding machines can weld plastics used in household appliances like refrigerators, washing machines, and dishwashers. The welds are durable and resistant to wear and tear, resulting in longer-lasting appliances that require less maintenance.

210-260HZ 6KW/8KW/15KW/18.5KW/30KW

100-125HZ 37KW

Our Vibration Trajectory Control Technology improves performance and quality through High Frequency and Friction Efficiency. These features allow for maintaining a consistent amplitude and utilizing the AMPA driving mode.

We offer several other capabilities that set our technology apart in the market. For example, our technology provides controllable linear output power, as well as an automatic fast resonance frequency function. This ensures that our system always operates at optimal levels, delivering high-quality results every time.

Our Vibration Trajectory Control Technology is designed to enhance performance and quality in welding. With features such as welding quality judgement, staged welding, and multi-mode depth and time welding, our technology is state-of-the-art. It also includes an automatic welding parameter saving function, multi-language operation interface, and easy-to-use touch smart control system. Our technology is equipped with mold number identification, automatic vacuum suction, and fixture action programming control to ensure safety and reliability. We prioritize safety with features such as mold safety protection, external function expansion, and multiple sound insulation protection devices. These features ensure safe and reliable operation, while also improving performance and quality. Our technology is available in various table sizes and tooling weight considerations, making it an efficient solution for welding various parts. With its solid welded tubular steel frame construction and large mechanical mass of the linear vibration head, our technology ensures machine stability and prevents machine failure due to process vibration.

Inspiration Photos

Quote Now

Quote Now