Unveiling the Science Behind Ultrasonic Atomization

Ultrasonic atomization is a cutting-edge technology that has revolutionized various industries, including pharmaceuticals, healthcare, nanotechnology, agriculture, and cosmetics. By harnessing high-frequency ultrasonic vibrations, this process breaks down liquid substances into tiny droplets, creating a fine mist or spray. The precise and controlled atomization provided by ultrasonic waves offers numerous advantages, such as reduced waste, improved efficiency, and enhanced product quality. In this article, we will delve into the science behind ultrasonic atomization, exploring its applications, benefits, and future prospects.

The Fundamentals of Ultrasonic Atomization

Understanding Ultrasonic Waves

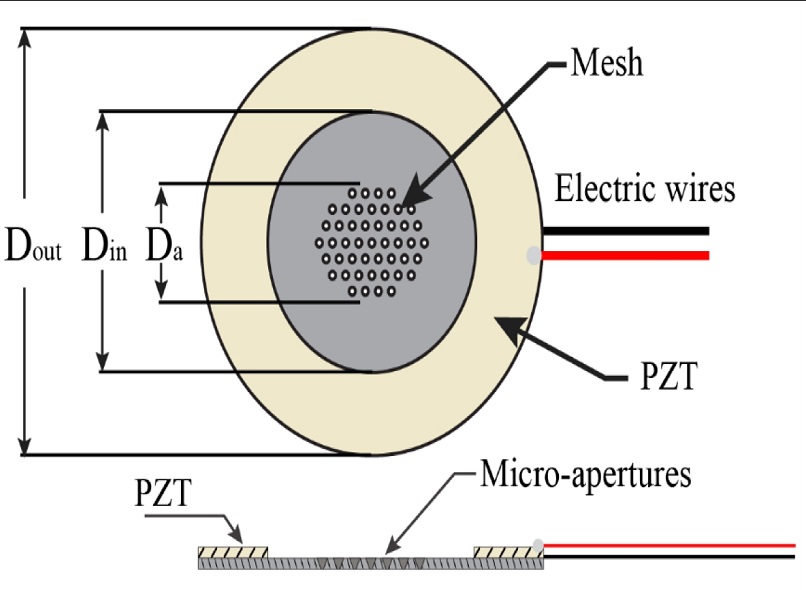

Ultrasonic waves refer to sound waves with frequencies above the upper limit of human hearing, typically above 20,000 Hz. These waves are generated by ultrasonic atomizers, which consist of a transducer and a resonator. The transducer converts electrical energy into mechanical vibrations, while the resonator amplifies and focuses these vibrations.

Atomization Process

When the ultrasonic waves pass through a liquid, they create localized pressure variations, leading to the formation of tiny bubbles. These bubbles undergo rapid expansion and contraction due to the alternating pressure waves, resulting in the disruption of the liquid's surface tension. As a result, the liquid breaks up into small droplets, forming a fine mist or spray.

Advantages of Ultrasonic Atomization

The precise control over droplet size and distribution achieved through ultrasonic atomization offers several advantages. Firstly, it ensures uniform coverage and dispersion of substances, making it ideal for applications such as drug delivery, where accurate dosing is crucial. Additionally, ultrasonic atomization reduces waste by minimizing overspray and allows for the use of smaller quantities of liquid, leading to cost savings. Furthermore, the fine mist created by ultrasonic atomization increases the efficiency of processes such as coating, where a thin and even layer is desirable.

Applications of Ultrasonic Atomization

Healthcare and Pharmaceuticals

Ultrasonic atomization plays a vital role in the healthcare and pharmaceutical industries. It enables precise drug delivery methods, ensuring that medications reach their intended targets with enhanced effectiveness. By atomizing active pharmaceutical ingredients (APIs) into fine droplets, ultrasonic atomization ensures consistent dosages and efficient absorption by the body. This technology also facilitates the production of inhalable medications, allowing for targeted treatment of respiratory conditions.

Nanotechnology and Electronics

In the field of nanotechnology, ultrasonic atomization is used to create nanomaterials with unique properties. By atomizing precursor solutions containing nanoparticles, ultrasonic atomizers produce uniform and controlled droplets that can be used in various applications, including electronics, coatings, and energy storage. This precise control over droplet size is crucial for the synthesis of functional nanoparticles with specific characteristics.

Agriculture and Pesticide Application

Ultrasonic atomization has found its way into agricultural practices, particularly in pesticide application. By atomizing pesticides into fine droplets, this technology ensures uniform coverage of crops while minimizing the environmental impact. The precise control over droplet size allows for efficient and targeted application, reducing the amount of pesticide needed and preventing unnecessary contamination.

Cosmetics and Personal Care Products

The cosmetic industry has embraced ultrasonic atomization for the production of fine mists in beauty and personal care products. By atomizing liquid formulations, such as perfumes and facial sprays, into fine droplets, ultrasonic atomizers create a pleasant and even application experience for users. This technology also allows for the incorporation of active ingredients in cosmetics, ensuring their effective delivery and absorption by the skin.

Advancements in Ultrasonic Atomization: Transforming Industries

Enhanced Control and Customization

Recent advancements in ultrasonic atomization technology have focused on improving control and customization options. Manufacturers now offer atomizers with adjustable frequency and power settings, allowing for precise control over droplet size and distribution. This level of customization enables industries to tailor atomization processes to specific applications and achieve desired outcomes.

Integration with Automation Systems

Another significant advancement is the integration of ultrasonic atomization systems with automation technologies. By connecting atomizers to programmable logic controllers (PLCs) and sensors, industries can automate the atomization process, ensuring consistent and reliable performance. This integration also enables real-time monitoring and adjustment of atomization parameters, enhancing efficiency and reducing human error.

Miniaturization and Portability

Advances in ultrasonic atomization have led to the development of compact and portable atomizers. These miniaturized devices offer greater flexibility and ease of use, allowing for atomization in confined spaces or on the go. This portability has expanded the range of applications for ultrasonic atomization, making it accessible in various settings, including laboratories, clinics, and field operations.

Energy Efficiency and Sustainability

Energy efficiency and sustainability have become crucial considerations in modern industries. Ultrasonic atomization offers advantages in these areas by reducing waste and energy consumption. The precise control over droplet size minimizes overspray, leading to significant material savings. Furthermore, ultrasonic atomization requires lower energy input compared to traditional atomization methods, contributing to overall energy efficiency and environmental sustainability.

Ultrasonic Atomization: The Future of Drug Delivery Systems

One area that holds immense promise for ultrasonic atomization is the development of advanced drug delivery systems. The precise control over droplet size and distribution provided by ultrasonic atomization opens up opportunities for targeted drug delivery to specific body tissues or organs. This technology can enhance the effectiveness of medications, reduce side effects, and improve patient outcomes.

The Role of Ultrasonic Atomization in Industrial Applications

Ultrasonic atomization has become an indispensable tool in various industrial applications. In the manufacturing sector, it is used for coating, surface treatment, and the production of advanced materials. The precise dispersion and uniform coverage offered by ultrasonic atomization result in high-quality finishes and improved product performance. Additionally, this technology finds applications in the production of nanomaterials, where controlled droplet size is crucial for achieving desired material properties.

Understanding the Environmental Impacts of Ultrasonic Atomization

As with any technological advancement, it is essential to consider the environmental impacts of ultrasonic atomization. While this technology offers benefits such as reduced waste and precise dosing, it is crucial to ensure responsible use and disposal of atomized substances. Industries must adhere to proper waste management practices and consider the environmental implications of the chemicals used in the atomization process. Additionally, ongoing research is necessary to assess the long-term effects of ultrasonic atomization on the environment and human health.

Conclusion

Ultrasonic atomization is a groundbreaking technology that has transformed various industries, offering precise control over droplet size and distribution. From healthcare and pharmaceuticals to agriculture and cosmetics, this technology has found applications in diverse sectors. Advancements in ultrasonic atomization continue to drive innovation, enabling enhanced control, automation, and customization. As industries seek more efficient and sustainable solutions, the future of ultrasonic atomization looks promising, particularly in the field of drug delivery systems. However, it is crucial to balance the benefits of this technology with environmental considerations, ensuring responsible use and minimizing potential impacts. With its wide-ranging applications and ongoing advancements, ultrasonic atomization is set to shape the future of numerous industries.