Robotic Welder & Automatic Welding: Benefits & Applications

A recent study says that the global robotic automatic welding market is estimated to reach up to $27.74 billion by 2030.

With technological advancements in vehicle production, manufacturers are now looking for smarter, faster, and more reliable solutions. One such reliable welding technique is robotic ultrasonic welding, which is transforming how cars are built.

Dizo's ultrasonic robotic welder offers 99.9% consistency in bond strength and production efficiency. Let's know how robotic ultrasonic spot welding works, its applications, and how Dizo robotic automation welding outperforms traditional welding techniques.

Table of Contents

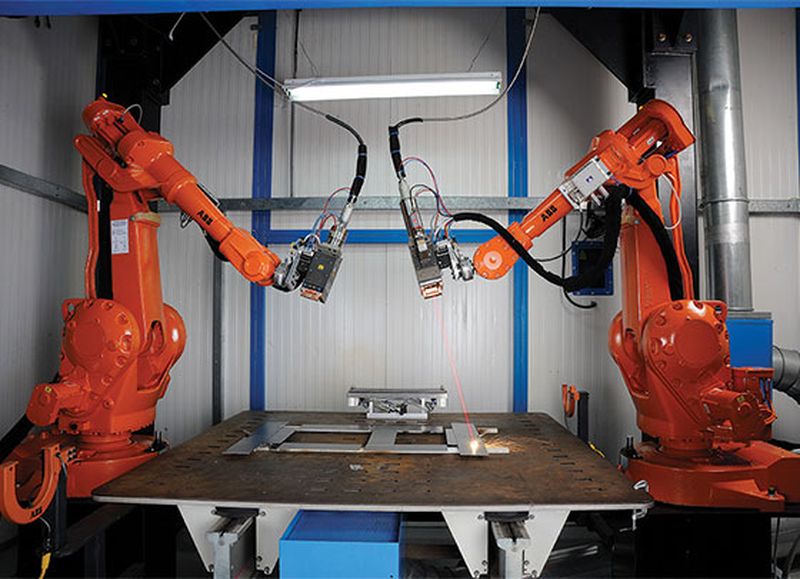

What is Automation Robotic Welding

How Does a Robotic Welder Work?

Benefits of Automatic Robotic Welding

Applications of Automatic Ultrasonic Spot Welder in the Automotive Industry

Why Choose a Dizo Robot Automatic Welding Equipment?

Conclusion

FAQs

What is Automation Robotic Welding

Robotic ultrasonic spot welding is an innovative manufacturing technique that uses mechanical ultrasonic vibrations of high frequency (typically 20-40 kHz) to fuse plastic parts of vehicles, such as bumpers, dashboards, and door panels.

The vibrations create friction at the contact surface, which melts the material, and the components are fused. It performs the bonding process without using visible adhesives or bolts.

In this automatic ultrasonic welding method, robots are programmed to automate the intricate welding patterns consistently. For welding automation companies, this technique is most efficient for thermoplastics and lightweight metals like aluminum and copper.

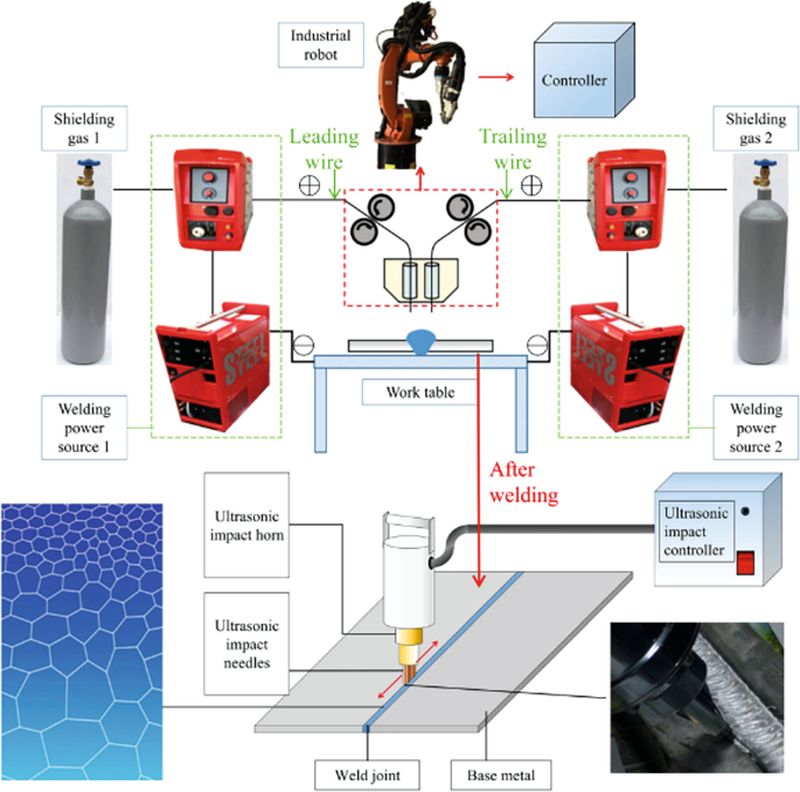

How Does a Robotic Welder Work?

In the process of robotic ultrasonic welding, the following steps are involved: <How does ultrasonic welding work>

Components Loading and Positioning

First, the plastic parts to be welded are loaded into fixtures and fixed at a precise position. Then, the robotic arm accurately aligns the ultrasonic horn at the weld position.

Clamping

The parts are fastened together to make intimate contact at the interface. Pressure is applied through fixtures to hold the components together.

Apply Ultrasonic Vibration

The ultrasonic horn applies high-frequency vibrations at the contact surface, which generates heat through friction. The heat softens the material.

Bonding

The molten material intermixes and fuses together under pressure.

Benefits of Automatic Robotic Welding

From automating the welding assembly to ensuring high-quality, leak-proof seams, ultrasonic welding has revolutionized in various ways. It offers many benefits for welding automation companies, including:

Boosts Production Efficiency

With operation cycles as fast as 0.1-1.5 seconds, the robotic ultrasonic welding automation system enhances production accuracy.

Robotic arms are programmed for quick-change molds, which accelerates the large-scale production process with minimum manual effort. Real-time sensors enable error-free welds by giving feedback along the process.

Cost Reduction

Robotic automated welding system minimizes cost savings by cutting down labor, material, and energy expenses.

A single robot can replace 3-5 skilled workers on average, leading to a 30-50% reduction in labor costs. It outperforms human labor, and there are fewer chances of errors in this technique.

Environmental Sustainability

Environmental friendliness is another key benefit that makes automated robotic welding the best choice for automotive manufacturers.

It causes zero emissions of VOCs and hazardous chemicals in the environment. During the automated welding process, mechanical vibrations produce heat through friction at the contact surface.

Since there is less consumption of external energy, which leads to fewer emissions of heat or waste.

Elimination of Consumables

Unlike traditional welding techniques that require adhesives or fasteners to fuse components, automated ultrasonic welding machines rely on high-frequency vibrations to melt and join materials.

Therefore, it reduces the operational costs and material waste considerably. The robotic welder is an ideal choice for automotive manufacturers who aim at larger-scale production, efficiency, and high-precision vehicle assembly.

Applications of Automatic Ultrasonic Spot Welder in the Automotive Industry

Robotic welding system has proven to be a game-changer technique for the automotive industry. It solves real-world problems in a much more efficient way than traditional welding techniques. Some major applications are;

Dashboard Assembly

Automated robotic welding has revolutionized dashboard assembly welding in modern vehicles. Unlike other methods like thermal welding or adhesive joining, it uses high-frequency vibrations to join the thermoplastics in milliseconds with high precision.

Headlight Housing Assembly

Welding automation system has transformed the way headlights are built by making the process faster and durable. It joins the two main plastic parts of the headlight–the front lens and the back housing. That blocks the dust, water, and moisture and protects the headlight from damage.

Acoustic Insulation

Strong acoustic insulation in vehicles is very important to keep the sound levels low. Ultrasonic welding joins the acoustic materials like foam or fibre mats that are attached to the plastic parts like door panels or floors.

Door Panel and Trim Welding

In traditional methods, adhesives or fasteners were used to join the parts, like the door panel, which caused visible marks or bonding failure over time.

Ultrasonic robotic welding has replaced it with smooth bonding between such materials without affecting the surface texture. Modern vehicles are designed with door trims like decorative stitching and lightning features.

Automated ultrasonic welding machine ensures invisible welds at complex shapes with complete accuracy.

Engine Compartment Assembly

In the engine compartment, even a minor leak can affect engine performance and efficiency. The parts, such as fluid reservoirs, engine covers, and cable channels, can be strongly welded through ultrasonic welding.

Mechanical vibrations create strong seals without affecting material quality while maintaining shape under high-pressure and temperature loads.

Why Choose a Dizo Robot Automatic Welding Equipment?

Dizo's Robotic Ultrasonic Welder is designed specifically to meet the demands of automotive interior manufacturing. We'll explore its key features that make it a standout solution and the ideal choice for manufacturers. <How to use a plastic welder>

Versatile Product Welding

Robot automatic ultrasonic welding is equipped with a quick-change mold system, which enables fast and efficient switching between different automotive components.

Along with its quick switching capability, it also provides exceptional weld quality without compromising on its structure and the visual appeal of the product.

Centralized Control System

The Dizo robot automatic spot welder features a simple and easy-to-use computer interface that allows the operators to control the complete welding system. Its user-friendly and streamlined design enables the operator to manage it easily without any special training.

Stable and Efficient Cooling

It also has a precision temperature control system. During the welding operation, it maintains the optimal temperature at the interface, which prevents the material shape from distortion due to thermal expansion. It also delivers consistency despite changing air pressure.

Precision Welding Design

Another key feature of the Dizo automatic spot welding machine is its use of advanced amplitude technology for targeting efficient energy transfer during the welding process.

It results in strong and accurate welds. Additionally, the automated welding equipment is designed in a way to minimize the acoustic resistance, which leads to lower use of energy.

High-accuracy welding

Dizo's robotic ultrasonic automatic welding equipment uses a dual-layer sensor system that monitors the welding process and gives real-time feedback. By continuously observing the parameters, it also maintains weld strength and accuracy through the operation.

Conclusion

By replacing traditional methods, automatic robotic ultrasonic welding is reshaping the future of automotive manufacturing. It provides cleaner, faster, and more cost-effective solutions for assembling modern vehicles.

Dizo's robotic ultrasonic welder is a true game changer, not only does it deliver exceptional product quality but it also features eco-friendly technology. Our automatic welding equipment is designed to upgrade your production line to the next level.

FAQs

1. Is this robotic ultrasonic welding only for plastics, or can it also weld metals?

It can weld both. For plastics, it performs the welding by heating the material and creating strong bonds. In the case of lightweight metals like aluminum or copper, it welds without heating the material. However, thick metals like stainless steel require other welding techniques.

2. Why is robotic ultrasonic welding preferred over traditional welding or adhesives?

Its fast speed, efficiency, and precision make it better than traditional welding. It can fuse parts in 0.1-1.5 seconds, much faster than the adhesives. There are no visible bolts or screws. Moreover, it's eco-friendly as there is no need for consumables and no emissions or fumes.

3. Is robotic ultrasonic welding expensive as compared to other techniques?

Yes, initially, it's expensive to implement. However, for welding automation companies who aim at high-precision and large-scale production, this method is a cost-effective process. It reduces manual labor and workforce and enhances faster production.

4. What plastic parts in cars are welded by this technique?

Plastic parts like bumpers, door panels, dashboards, trim components, and headlights can be welded by robotic welding.