How to Calculate the Energy Required for Ultrasonic Welding

Ultrasonic welding is a widely used process for joining plastics and metals. It uses high-frequency vibrations to generate frictional heat, which melts and fuses the materials together. To ensure that the welding process is successful, it is essential to calculate the energy required for ultrasonic welding accurately. This article will explain how to calculate the energy required for ultrasonic welding.

Understanding Ultrasonic Welding

Ultrasonic welding is a process that uses high-frequency vibrations to generate frictional heat that melts and fuses materials together. The process involves the use of an ultrasonic welding horn, which is placed on top of the materials to be joined. The horn is then vibrated at high frequency, typically between 15 kHz and 40 kHz, which generates heat due to friction between the materials. This heat melts the materials, allowing them to fuse together when the vibrations stop.

Factors Affecting Energy Required for Ultrasonic Welding

The amount of energy required for ultrasonic welding depends on several factors, including the type and thickness of the materials being welded, the design of the ultrasonic welding horn, and the energy director. The energy director is a raised feature that is designed into one of the parts to be welded. It concentrates the energy of the ultrasonic vibrations into a specific area, which increases the efficiency of the welding process. The size, shape, and location of the energy director will influence the amount of energy required for ultrasonic welding.

Calculation of Energy Required for Ultrasonic Welding

The energy required for ultrasonic welding can be calculated using the following formula:

E = 0.5 x Q x V x (T1 + T2)

Where:

- E: Energy required (Joules)

- Q: Quality factor (typically 1)

- V: Amplitude of the ultrasonic vibrations (micrometers)

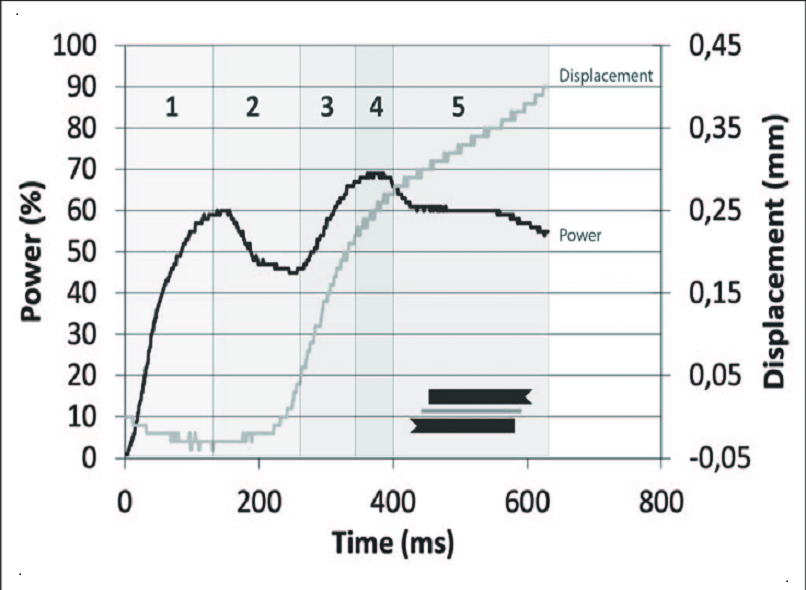

- T1: Time to reach the amplitude (milliseconds)

- T2: Welding time (milliseconds)

The quality factor (Q) is a unitless value that accounts for the efficiency of the welding process. A value of 1 is typically used for most applications.

The amplitude (V) is the maximum displacement of the ultrasonic vibrations. It is determined by the design of the ultrasonic horn and the frequency of the vibrations.

The time to reach the amplitude (T1) is the time required for the ultrasonic vibrations to reach the maximum amplitude. It is determined by the design of the ultrasonic horn and the frequency of the vibrations.

The welding time (T2) is the time required to complete the welding process. It is determined by the thickness and type of the materials being welded, as well as the design of the energy director.

Importance of Accurate Calculation

Accurately calculating the energy required for ultrasonic welding is crucial to ensure that the welding process is successful and efficient. If too little energy is applied, the materials may not fuse together completely, resulting in a weak joint. If too much energy is applied, the materials may be damaged or deformed, resulting in a poor-quality joint. Therefore, it is essential to calculate the energy required for ultrasonic welding accurately.

Calculating the energy required for ultrasonic welding is an essential step in ensuring a successful and efficient welding process. By identifying the energy director and using the above formula, you can accurately calculate the energy required for ultrasonic welding. Understanding the factors that affect the energy required for ultrasonic welding and the importance of accurate calculation can help you achieve optimal results in your welding process.