A Comprehensive Guide on Vibration Welding for Dishwasher Pumps Assembly

With the advancement of technology, the process of joining components has evolved drastically. One such innovative technique is vibration welding, which is highly effective for assembling dishwasher pumps. In this guide, we will take a deep dive into the process, advantages, and applications of vibration welding in the dishwasher pumps assembly.

1. Understanding Vibration Welding

Vibration welding is an industrial process that utilizes frictional heat to bond thermoplastic parts together. One part is held stationary in a holding fixture, while the other part is vibrated against it under controlled pressure. The friction created between the parts produces heat, causing the polymer at the joint to melt and form a strong, hermetic seal upon cooling.

2. The Advantages of Vibration Welding

Vibration welding offers several benefits, making it an excellent choice for various applications, including dishwasher pumps assembly. Some of the key advantages include:

- Efficiency: Vibration welding is known for its short cycle times, making it an energy-efficient process.

- Versatility: It is compatible with most thermoplastics, even those that are difficult to weld, such as glass-filled nylon, polypropylene, and polyethylene.

- Strength: Vibration welding can produce high-strength, leak-proof hermetic seals, ensuring durability.

- Flexibility: It can weld multiple parts in a single cycle, offering flexibility in production.

3. The Disadvantages of Vibration Welding

Despite its numerous advantages, vibration welding also has a few drawbacks. These include the requirement for specially designed tooling fixtures and the limitation of the technique to certain types of materials and shapes. However, the benefits often outweigh these drawbacks in many applications.

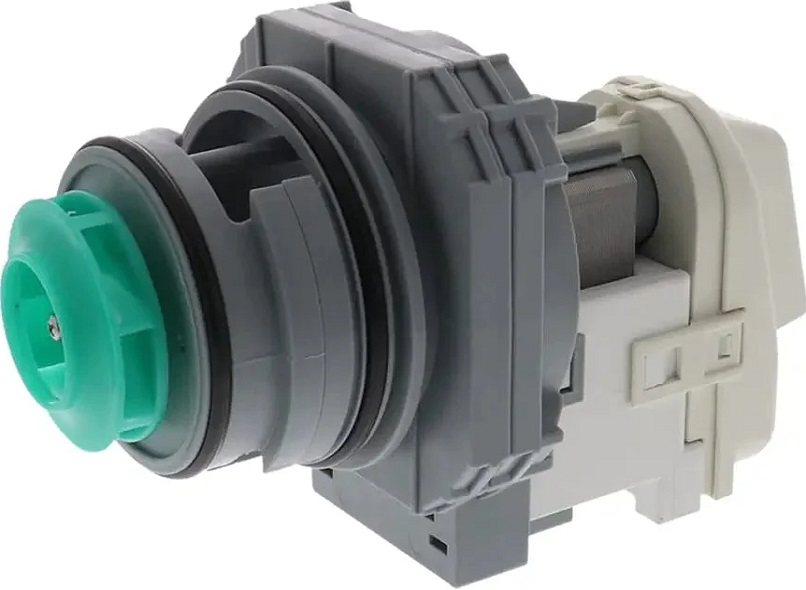

4. Vibration Welding in Dishwasher Pumps Assembly

The dishwasher pump assembly is one area where vibration welding has found significant application. This method is particularly effective in creating hermetic seals in the pump, which are essential for maintaining pressure and preventing leaks. The high strength of the welds also ensures the durability of the assembly, enhancing the overall performance and longevity of the dishwasher.

Copy codeDishwasher pump assembly using vibration welding

5. The Process of Vibration Welding in Dishwasher Pumps Assembly

In the dishwasher pumps assembly, the vibration welding process follows some specific steps. These include:

- Preparation: The parts to be welded are prepared and cleaned to remove any contaminants.

- Placement: One part is placed in a stationary holding fixture, while the other is set in a vibrating head.

- Application of Pressure and Vibration: The vibrating head moves the part at a high frequency under controlled pressure against the stationary part.

- Melting and Bonding: The friction produced generates heat, which melts the plastic at the joint interface. The molten plastic flows out of the weld zone, forming a bond as it cools and solidifies.

- Cooling and Unloading: After the vibration stops, the parts are cooled under pressure and then unloaded.

6. Choosing the Right Vibration Welding Machine

Selecting the right vibration welding machine is crucial for achieving optimal results in dishwasher pumps assembly. Factors to consider when choosing a machine include:

- Size and Weight Capacity: The machine should be able to accommodate the size and weight of the parts to be welded.

- Control Features: Look for a machine that offers adjustable amplitude, time, and force controls for precise operation.

- Drive System: Consider machines with advanced drive systems, such as digital servo drives, for improved performance and power.

7. Vibration Welding Tooling

The tooling used in vibration welding is essential for achieving a successful weld. The tooling must provide constant, uniform pressure across the weld joint and ensure that the parts sense the uniform relative amplitude generated by the welding machine. Improper tool design can result in a loss of process control and the production of nonconforming parts.

8. Newer Technologies in Vibration Welding

New technologies have further enhanced the capabilities of vibration welding. For instance, Clean Vibration Technology (CVT) minimizes flash and particulate formation, making it suitable for applications requiring cleaner welds.

9. Alternative Welding Techniques

Apart from vibration welding, other welding techniques are also used in the assembly of dishwasher pumps. These include ultrasonic welding, infrared welding, and hotplate welding. The selection of the appropriate technique depends on the specific requirements of the application.

10. Advantages of Working with Professional Vibration Welding Services

Working with professional vibration welding services offers several benefits, such as access to expert knowledge, high-quality equipment, and comprehensive services. Such services can help ensure optimal welding results, reduce downtime, and enhance the overall efficiency of the assembly process.

11. The Future of Vibration Welding

With continuous advancements in technology, the future of vibration welding looks promising. Innovations in machine design, control systems, and tooling are expected to further improve the efficiency and effectiveness of the process, opening up new possibilities for its application in various industries.

12. Conclusion

Vibration welding is a highly effective technique for assembling dishwasher pumps. Its ability to create strong, hermetic seals makes it a valuable tool in the production of durable, high-performing dishwashers. By understanding the process and leveraging the right equipment and professional services, businesses can harness the full potential of vibration welding for their assembly needs.

This comprehensive guide should serve as a valuable resource for anyone looking to understand the role of vibration welding in dishwasher pumps assembly. With its detailed insights and practical tips, it provides the knowledge needed to make informed decisions and achieve optimal results in the assembly process.